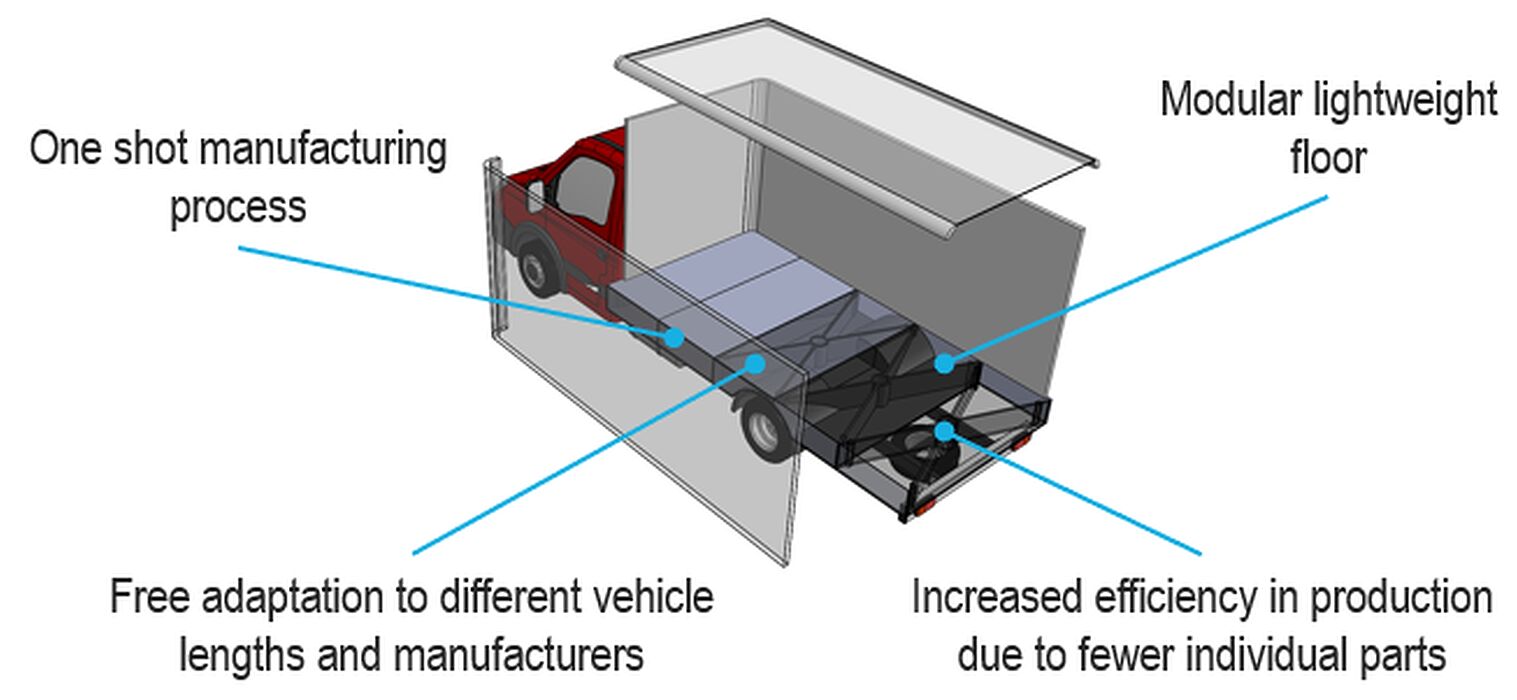

The 27th Jour Fixe 'New Processes: Composites in the Automotive Industry' took place on 21 October, with around 30 CU members and guests discussing using fibre-reinforced plastics and how they're likely to develop in the future. The ILH was represented by Mr Julian Lückenkötter, who presented a paper on the process development of a box body floor assembly for vehicles in the 3.5t class. The background to the project, funded by the German Federal Ministry of Economics and Climate Protection, is the increasing volume of parcels. This makes it essential for parcel delivery companies to expand their vehicle fleets, leading to increased emissions. So far, the vehicle body consists of an aluminium lattice structure and a wooden body. In order to reduce the weight of these vehicles and the resulting emissions and to increase the payload, a modular floor assembly made of glass fibre mat-reinforced thermoplastics (GMT) was developed. It was produced by compression molding and can be used for different vehicle models. The first step was to optimise the topology of the floor module to make the best use of the available space. This was followed by material characterisation and the development of the manufacturing process and tooling concept. After the demonstrator was produced, the floor module was installed in a pilot vehicle and subjected to a long-term test to evaluate the vehicle's performance.

Speaker Julian Lückenkötter, Team Leader Materials & Processes, Institute for Lightweight Design with Hybrid Systems (ILH), Paderborn University

Event information (only available in German)