Maximilian Kaiser

Research Associate

Team leader Materials and Processes

- E-Mail:

- maximilian.kaiser@uni-paderborn.de

- Phone:

- +49 5251 60-4512

- +49 2955 7610-469

-

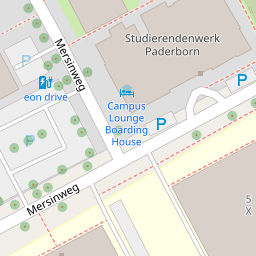

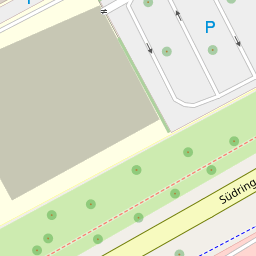

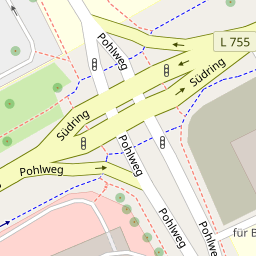

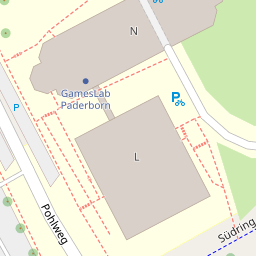

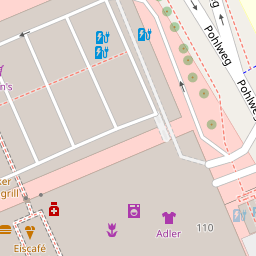

- Office Address:

-

Mersinweg 7

33100 Paderborn - Room:

- Y1.208

Sustainability and future-oriented mechanical engineering can only be united through consistent action

Research

Research Interests

- Sustainable wood-metal hybrids for the furniture industry

- Titanium hot forming for aerospace

- Metallic lightweight constructions

- Sheet metal forming

Publications

Selected Publications

Enhancing mechanical strength of Ti-6Al-4V sheet material by short-time sub-β-transus solution heat treatment and additional short-time annealing

N. Pfeffer, S.N. Jäger, M.A. Kaiser, T. Meyer, A. Stark, H.W. Höppel, Materials Science and Engineering: A 926 (2025).

The new TISTRAQ process: Solution treatment with rapid quenching and annealing for Ti-6Al-4V sheet metal part forming - investigation on heat transfer coefficient and influence on cooling rates

M.A. Kaiser, F. Höschen, N. Pfeffer, M. Merten, T. Meyer, T. Marten, P. Rockicki, H.W. Höppel, T. Tröster, in: IOM3. Chapter 14: Forming, Machining & Joining [Version 1; Not Peer Reviewed], 2024.

Advancements in Hybrid Additive Manufacturing: Integrating SLM and LMD for High-Performance Applications

D. Chalicheemalapalli Jayasankar, S. Gnaase, M.A. Kaiser, D. Lehnert, T. Tröster, Metals 14 (2024).

Untersuchung energieeffizienter und serientauglicher Erwärmungsstrategien mittels resistiver Erwärmung für den Presshärteprozess

M.A. Kaiser, A. Reitz, S. Konrad, T. Meyer, T. Marten, T. Tröster, in: M. Merklein (Ed.), Workshop Warmblechumformung, Lehrstuhl für Fertigungstechnologie, Erlangen, 2023, pp. 99–118.

Heat transfer coefficient investigation for hot die quenching process of Ti-6Al-4V alloy

M.A. Kaiser, P. Rockicki, F. Höschen, J.-N. Wesendahl, S. Konrad, T. Meyer, T. Marten, T. Tröster, in: 2022.

Show all publications